RoboFlex™ Automation & Robotics

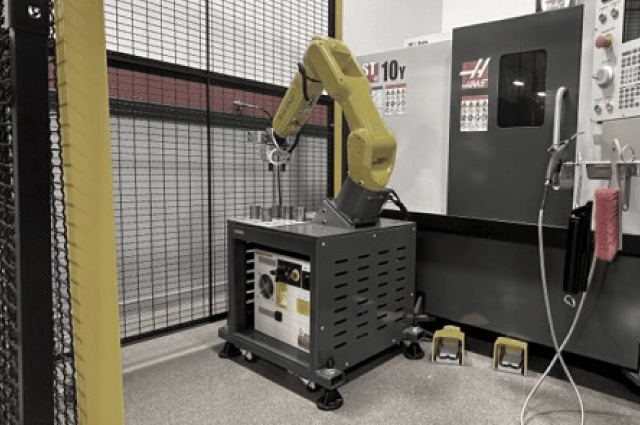

There are limited production hours available each year – make them count with a turnkey or custom robotics solution from RoboFlex™ by Productivity.

YEARS OF EXPERIENCE

(& COUNTING) SYSTEMS INSTALLED

DEDICATED AUTOMATION INTEGRATION EXPERTS

IN CNC AUTOMATION INTEGRATION

Unlock the full potential of your business or shop with automation. Automation in manufacturing can be your secret weapon to staying competitive and achieving maximum business results across the board.

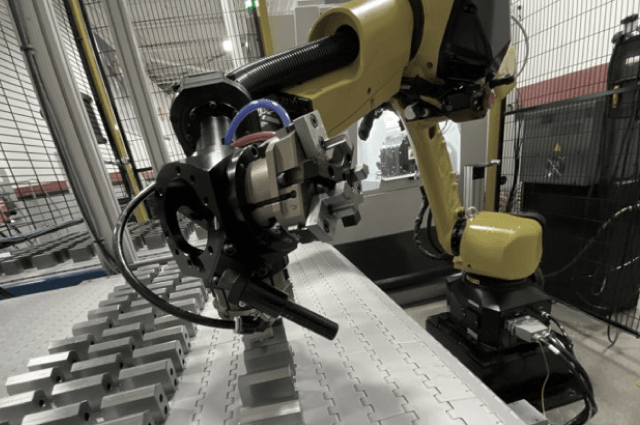

RoboFlex’s team of robotic integration specialists partners with you from concept through design and process, utilizing specialized tooling to develop flexible solutions for your manufacturing challenges. Increase production output, achieve faster ROI, maximize labor efficiency, and improve part quality.