Why Use a Bar Feeder

If you’re like most job shops, you’re always looking for ways to be more competitive. With the continued importance of just-in-time manufacturing, automating your turning production processes has never been more relevant. And, with the shortage of qualified manpower, automating your turning operations is a must. Integration of automation has proven to be a valuable asset in a machine shop’s arsenal of tools – Productivity’s automation and integration services can help you automate whether be through robotics integration, automatic parts loaders (APLs) or bar feeder systems.

If you’re like most job shops, you’re always looking for ways to be more competitive. With the continued importance of just-in-time manufacturing, automating your turning production processes has never been more relevant. And, with the shortage of qualified manpower, automating your turning operations is a must. Integration of automation has proven to be a valuable asset in a machine shop’s arsenal of tools – Productivity’s automation and integration services can help you automate whether be through robotics integration, automatic parts loaders (APLs) or bar feeder systems.

Enter – the bar feeder.

In the early days of manufacturing, the machine operators were the bar feeders. They would load, hold and guide the bar stock by hand which meant the machine had to run at slower RPMs. With longer bar lengths, this was not optimal nor safe for the machine operator – the bar would hang out the back of the machine resulting in dangerous bar whip and undesirable vibration followed, causing damaged spindles, shorter tool life and poor part accuracy. Since then, bar feeders have evolved into indispensable, user-friendly, worker-friendly, highly efficient, automation accessories.

Automatic bar feeders, a.k.a. bar loaders, magazine bar feeders, spindle-length loaders and short loaders, are the most commonly used automation accessories in the metalworking industry. Generally applied to turning machines and sliding headstock Swiss lathes, they are designed to deliver a continuous supply of raw machining stock in the form of round, hex, square, and extruded shapes for the manufacture of parts.

Automatic bar feeders, a.k.a. bar loaders, magazine bar feeders, spindle-length loaders and short loaders, are the most commonly used automation accessories in the metalworking industry. Generally applied to turning machines and sliding headstock Swiss lathes, they are designed to deliver a continuous supply of raw machining stock in the form of round, hex, square, and extruded shapes for the manufacture of parts.  While seemingly simple in nature and relatively economical in price, bar feeders perform an important repetitive, time-consuming task that makes them invaluable in many shop environments. The right bar feeder will free up your machine operators allowing them to focus on other priority tasks and/or monitor multiple projects or machines thereby increasing productivity and throughput. This is accomplished by the bar feeder’s ability to manage raw materials and minimize changeovers without operator intervention.

While seemingly simple in nature and relatively economical in price, bar feeders perform an important repetitive, time-consuming task that makes them invaluable in many shop environments. The right bar feeder will free up your machine operators allowing them to focus on other priority tasks and/or monitor multiple projects or machines thereby increasing productivity and throughput. This is accomplished by the bar feeder’s ability to manage raw materials and minimize changeovers without operator intervention.

Bar Feeder Classifications

Hydrodynamic bar feed systems are bar feeders where the bar stock sits in a feed tube surrounded by pressurized oil that supports the spinning bar as well as pushes the bar through the feeder. Because of the oil-filled tube, there is less noise and vibration. Most hydrodynamic bar feeders require the operator to manually feed in one bar at a time and feed tubes must be changed if the diameter of the bar changes. Due to some of their limitations, they generally cost less than hydrostatic bar feeders.

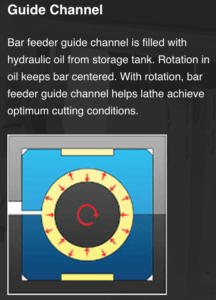

(1)Hydrostatic bar feed systems are bar feeders where the bar rests in a series of guide channels or bushings that clamp around the stock to hold it in place during machining. Large volumes of hydraulic fluid are pumped into each channel, surrounding the bar in an oil film, thereby supporting the bar. In the meantime, the bar is being pushed by a servo motor rather than oil. Hydrostatic bar feeders can usually accommodate bar stock lengths ranging from 4 to 24 feet and various diameter bars without changeover, and are generally magazine-type loaders. If you’re running parts in large volumes, a hydrostatic magazine-style loader would be the best choice as it can provide unattended, continuous, lights-out, automated operations. The versatility and automatic feed features of the hydrostatic bar feeder systems make them usually more expensive than hydrodynamic bar feeders.

Bar Feeder Sizes

As discussed, bar feeders are either hydrodynamic or hydrostatic. Further defining automatic bar feeders are the length of them. They are broken down into short loaders and 12-foot bar loaders. The right bar feeder will help automate your turning operations thereby reducing the machinist’s time in handling bar stock and changeover times.

Short Bar Loaders and Spindle Length Bar Feeders

Short bar feeders or bar loaders can handle 2- to 6-foot length bar stock. Three and 4-foot bar feeders can contain the whole length of the bar in the machine spindle, a.k.a. spindle length bar feeders, and have become the industry standard for single-spindle lathe applications. These compact bar feeders are great when shop space is at a premium, and they carry a smaller price tag than the larger bar feeders. In dispelling the belief that a bar feeder needs to be only running the same part over and over, the short bar feeder is just as well suited to run small and medium batch production runs of the same parts, as well as small runs of different workpieces with frequent changeovers. Since the entire bar length can fit within the lathe headstock, it can run at higher RPMs for faster machining. Additionally, they allow for easy setups and quick changeovers, and do not require the bar to be perfectly straight or prepped. When used with spindle liners, short loaders can run a variety of different diameter bar stock without operator intervention, making them ideal for unattended machining.

Short bar feeders or bar loaders can handle 2- to 6-foot length bar stock. Three and 4-foot bar feeders can contain the whole length of the bar in the machine spindle, a.k.a. spindle length bar feeders, and have become the industry standard for single-spindle lathe applications. These compact bar feeders are great when shop space is at a premium, and they carry a smaller price tag than the larger bar feeders. In dispelling the belief that a bar feeder needs to be only running the same part over and over, the short bar feeder is just as well suited to run small and medium batch production runs of the same parts, as well as small runs of different workpieces with frequent changeovers. Since the entire bar length can fit within the lathe headstock, it can run at higher RPMs for faster machining. Additionally, they allow for easy setups and quick changeovers, and do not require the bar to be perfectly straight or prepped. When used with spindle liners, short loaders can run a variety of different diameter bar stock without operator intervention, making them ideal for unattended machining.

Short bar feeders do have some limitations. The obvious one is that they can only hold a minimal amount of material, making them less desirable for longer part runs. They also require that the bar to be cut to spindle length which increases prep time and adds additional cost. Furthermore, they produce more remnants which can be costly particularly when turning expensive bar stock such as Inconel or titanium.

12-Foot Bar Feeders or Long Loaders

Most 12-foot automatic bar feeders are magazine-style loaders that can hold multiple bars. They are especially good for expensive materials as they are more efficient at bar utilization which means fewer or shorter remnants. They also boast fast cycle times and can run unattended for long periods making them the perfect loader for high count part-production runs. These magazine feeders are also ideal when the workpiece is longer than 8 inches, or if the job requires only a few changeovers.

Most 12-foot automatic bar feeders are magazine-style loaders that can hold multiple bars. They are especially good for expensive materials as they are more efficient at bar utilization which means fewer or shorter remnants. They also boast fast cycle times and can run unattended for long periods making them the perfect loader for high count part-production runs. These magazine feeders are also ideal when the workpiece is longer than 8 inches, or if the job requires only a few changeovers.

The foremost disadvantage of 12-foot bar feeders is their length. These long bar feeders take up about 14 feet of floor space plus require additional space to move around it. Another obvious downfall with feeders using longer bar stock, is the fact that the bar stock is not always straight. As a result, they have a history of causing bar whip and vibration, which will affect the part tolerance and finish. The fix is to have the machine run at reduced RPMs, which unfortunately affects throughput. Of course, polyurethane spindle liners and guide channels have helped with this issue as has using centerless ground bar stock in your Swiss-style turning machine, thus allowing a machinist to feed 12-foot bars up to 2 inches in diameter at or near maximum spindle speeds.

Bar Feeder Benefits

- Reduces operator intervention by freeing up the operator for other duties such as inspection, running another machine or setting up the next job

- Enhances machine operator safety

- Precision bar loading and bar stock support

- Allows lathe to operate at maximum spindle speeds

- Reduces material waste

- Enables unattended or lights-out manufacturing

- Less or faster changeovers

- Provides reliable and consistent operation

Factors to Consider When Choosing a Bar Feeder

All signs point to the fact that a bar feeder is a great addition to your turning operations. Before you decide which type and brand of bar feeder will meet your needs, you’ll need to consider several factors including:

- Your budget

- Machine capacity – bar feeder must be sized to the spindle

- Production run sizes – high volume vs short run jobs

- Ease and speed of changeover from job to job

- Range of bar stock diameters to be machined

- Length of parts being produced

- Type of material being used – standard or exotic

- Weight of materials being used

- Complexity of the part

- Accuracy requirements

- Floor space considerations

- Length of unattended operation time required

- Connectivity – how well will the bar feeder integrate with your machine and manufacturing operation

Options available on the bar feeder ie. servo motor, anti-vibration control, remote access, extended bar options, quick-bar change features, sensors, load meters, checkpoint, visual monitoring display, adaptive speed control, extra storage, programming options, etc.

Options available on the bar feeder ie. servo motor, anti-vibration control, remote access, extended bar options, quick-bar change features, sensors, load meters, checkpoint, visual monitoring display, adaptive speed control, extra storage, programming options, etc.

Belly Up to a Bar Feeder with Productivity

If your current turning operations are using more manpower than raw materials, and the thought of automation seems out of your grasp, consider the small but rewarding step of adding an automatic bar feeder to your turning machines. Their relatively low investment will allow your shop to eliminate tedious manual operations, enable your machinists to attend to multiple machines at once and allow for unattended or lights out manufacturing if needed, thereby increasing your overall productivity and bottom line. Reap the benefits of the automatic bar feeder – it could provide your shop with just the right boost to make your business more competitive in your market and beyond.

Productivity offers a large selection of brands of bar feeders including Citizen Cincom, Haas, LNS America, IEMCA and Edge Technologies to name a few. Contact your local Productivity sales representative today. They are experts at helping you choose the right bar feeder for your shop to ensure maximum compatibility and productivity.

Interested in using bar feeders for lights out operations, check out this article by LNS America.

Originally published 05/26/2015 | Updated 06/06/2022

(1)Diagram courtesy of Edge Technologies