Unlock Your Robot’s Potential: Integrating ATI Tool Change Solutions

Productivity wants your robot to go beyond just loading and unloading parts. See how Productivity automation engineers utilized ATI’s tool change products to maximize the FANUC robot’s capabilities!

ATI Industrial Automation is the world-leading engineering-based developer of robotic accessories and robot arm tooling, including Automatic Tool Changers, Multi-Axis Force/Torque Sensing Systems, Utility Couplers, Material Removal Tools, Robotic Collision Sensors, Manual Tool Changers, and Compliance Devices.

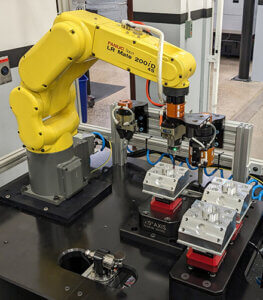

Productivity, a FANUC authorized system integrator, specializes in machine tool applications and custom automative solutions. Daniel Gerdin, an automation engineer at Productivity, recently worked on a project that incorporated ATI Industrial Automation’s tool change products with FANUC’s LR Mate 200iD 4S. FANUC, a Productivity partner since 1977, is the global leader in robotics. The ATI QC-11 Tool Changer plays a vital role in the demo pictured by facilitating the automatic exchange of robotic end-of-arm tooling. In addition, Productivity engineers utilized the RCT-151 Radially Compliant Deburring Tool along with a Renishaw probe. ATI’s end-effectors and a Renishaw probe on the FANUC robot arm enable seamless transitions throughout the process: from initial data collection using the probe, to executing precision deburring on the part, and ultimately, positioning the part for the subsequent cycle with a new unit.

the automatic exchange of robotic end-of-arm tooling. In addition, Productivity engineers utilized the RCT-151 Radially Compliant Deburring Tool along with a Renishaw probe. ATI’s end-effectors and a Renishaw probe on the FANUC robot arm enable seamless transitions throughout the process: from initial data collection using the probe, to executing precision deburring on the part, and ultimately, positioning the part for the subsequent cycle with a new unit.

Tool changers are engineered to ensure consistent performance over millions of cycles under full load, maintaining exceptional repeatability. Incorporating a tool change platform in robot cells not only enhances robotic capabilities, but also significantly reduces machining cycle times. ATI’s tool changers can be configured with a diverse range of standard add-on Utility Modules, facilitating support for various end-of-arm utilities and applications.

What can Productivity do for you? We specialize in designing custom automation systems. We analyze every aspect of your operation, from tool selection, NC process development, controller programming, cell layout, machine integration, multiple axis programming, and production ready processes.